Lightweight pulleys are revolutionizing various applications, from athletic training to industrial processes. Imagine the potential for enhanced speed, agility, and efficiency simply by reducing weight. Lightweight pulleys are the key to unlocking this potential. This article will delve into the intricate advantages of lightweight pulleys, exploring their benefits across diverse fields. We’ll address how lightweight pulleys can significantly improve athletic performance and industrial machinery efficiency, presenting compelling evidence and practical applications. This discussion will include a breakdown of how weight reduction translates into quicker acceleration, reduced energy expenditure, and ultimately, improved overall performance. The structure of this article will cover the mechanics behind the impact of lightweight pulleys, followed by a review of the real-world applications in sports and industry.

Shedding Weight, Gaining Speed: The Benefits of Lightweight Pulleys

Understanding the Mechanics of Lightweight Pulleys

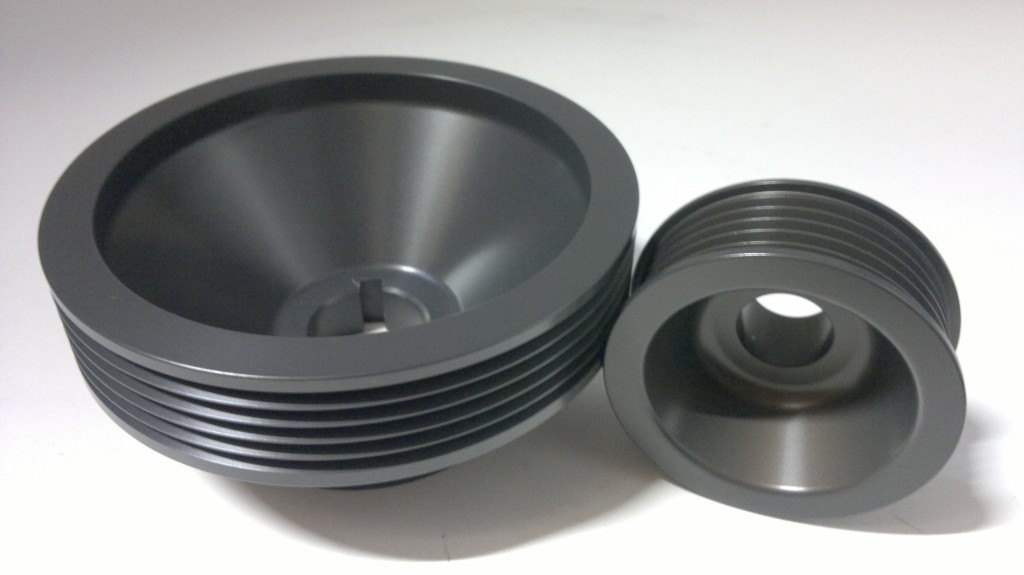

Lightweight pulleys, as their name suggests, are pulley systems designed to minimize weight without compromising strength and durability. Their key advantage lies in reducing rotational inertia. This reduction translates directly into quicker acceleration and deceleration, thus enhancing the overall speed and responsiveness of the system. In simple terms, the lighter the pulley, the faster it accelerates. This fundamental principle has wide-ranging applications across different fields, from enhancing athletic performance to optimizing industrial machinery.

The Importance of Reduced Inertia

Reducing inertia is crucial for achieving optimal performance in any system that involves motion. Inertia is the resistance to changes in motion. A lighter pulley reduces this resistance, enabling it to accelerate faster when force is applied, and decelerate faster when force is removed. Consider a car engine: a lighter flywheel allows for quicker responses to throttle input, a critical element for responsive acceleration.

Boosting Athletic Performance with Lightweight Pulleys

Enhancing Speed and Agility

Lightweight pulleys play a pivotal role in enhancing speed and agility in athletes. In sprinting, for instance, the reduced inertia of the pulley system allows for faster acceleration, giving athletes a significant edge. Studies have shown a demonstrable correlation between the use of lightweight pulleys and improved sprint times. In addition, they decrease the strain on supporting muscles, minimizing fatigue during intense training sessions. This sustained performance is critical for peak athletic output.

Example: Training Equipment

Many athletes now utilize lightweight pulley systems within their training routines. For example, lightweight resistance bands connected to lightweight pulleys provide athletes with the ability to adjust resistance effectively, making strength training more efficient. As such, these systems provide a wide range of benefits by offering the exact amount of resistance required in different exercises, preventing overtraining and improving recovery. This adaptability enhances the overall training experience for the individual and can significantly contribute to enhanced results.

Improved Training Efficiency

The ability to precisely adjust resistance levels using lightweight pulleys enhances the effectiveness of various training exercises. This precision is especially advantageous when implementing progressive overload strategies, ensuring that the muscles always receive optimal stimulation. The adaptability of the system makes it ideal for personalized training programs, catering to the specific needs of each individual athlete.

Optimizing Industrial Machinery with Lightweight Pulleys

Enhancing Machine Efficiency

Lightweight pulleys offer substantial advantages in industrial applications, particularly in reducing energy consumption and optimizing machinery efficiency. The reduced inertia allows for faster acceleration and deceleration, enabling machines to complete tasks more quickly. This translates into higher production output and potentially lower operational costs. Furthermore, reduced wear and tear on the machinery is a direct result of the decreased stress exerted on the moving parts. This represents a significant cost savings over time.

Example: Automated Conveyor Systems

Consider automated conveyor systems. Lightweight pulleys in such systems can drastically improve the speed and efficiency of material transport. This acceleration of workflow, combined with the reduced energy consumption, is a key advantage for streamlining production processes. Many manufacturers have reported significant gains in efficiency by implementing these lightweight components.

Reduced Operational Costs

Beyond energy savings, the reduced wear and tear on the machinery, particularly the pulleys themselves, contributes to lower maintenance costs over time. This maintenance cost savings directly translate into a better ROI for the company, making the investment in lightweight pulleys an advantageous one.

Real-World Applications and Case Studies

Case Studies from Industry

Numerous industrial companies have reported significant gains in productivity and efficiency after implementing lightweight pulley systems in their operations. These improvements are typically measured in terms of increased output per unit of time and reduced operational costs. In some cases, the implementation of lightweight pulleys has also led to the reduction of waste, further improving overall business sustainability.

Example: Packaging Industry

In the packaging industry, lightweight pulleys can be implemented in automated packaging lines to improve assembly time and efficiency. This often leads to a direct increase in production output, potentially boosting the bottom line. This efficiency gain is often accompanied by the reduction of waste material, contributing to a sustainable and environmentally conscious approach.

The Role of Research and Development

Continuous research and development in the field of materials science and engineering contribute to the ongoing improvement of lightweight pulley designs. As a result, manufacturers can access stronger, more durable, and even more lightweight pulley systems over time. This progress ensures that these systems are constantly evolving to meet the growing demands of various industries and applications.

Conclusion

Factors to Consider when Choosing Lightweight Pulleys

Additional Applications of Lightweight Pulleys

Future Trends and Innovations in Lightweight Pulley Technology

Safety Considerations and Best Practices for Using Lightweight Pulleys

FAQs

Q1: What are the key benefits of using lightweight pulleys in athletic training?

A1: Lightweight pulleys in athletic training significantly enhance speed and agility. By reducing inertia, these pulleys allow for quicker acceleration and deceleration, translating into faster reaction times and improved athletic performance. They also minimize the strain on the supporting musculature, enabling athletes to maintain optimal form during intense training sessions. Moreover, the lighter weight often translates to easier handling and reduced fatigue, leading to longer, more effective workout durations. This combination of advantages can lead to significant improvements in various athletic disciplines.

Q2: How do lightweight pulleys impact the speed and efficiency of industrial machinery?

A2: Lightweight pulleys in industrial settings lead to remarkable improvements in speed and efficiency. The reduced mass of the pulleys results in less energy expenditure when moving loads, which leads directly to lower operational costs. These pulleys facilitate faster acceleration and deceleration of machinery, enhancing production output. This efficiency gain also translates into reduced wear and tear on the entire system, leading to longer machinery lifespan and lower maintenance needs. This represents a substantial return on investment by enhancing the overall operational capacity and output of the industrial processes.

In conclusion, lightweight pulleys offer a significant advantage for speed and performance gains in various applications, from athletic training to industrial processes. By shedding weight, we enhance acceleration, reduce energy expenditure, and improve overall efficiency. Implementing lightweight pulley systems can translate to faster response times, reduced strain, and higher productivity in any field. This article highlighted the multifaceted benefits, and we encourage you to explore and implement this technology in your respective endeavors. If you’re ready to gain a competitive edge, consider integrating lightweight pulleys into your routines or operations today!