Sleek and efficient electric car aerodynamics play a pivotal role in defining the future of personal transportation. Imagine a world where electric cars not only deliver a smooth driving experience but also boast impressive range and performance, all while minimizing their environmental footprint. This ambitious goal necessitates a deep understanding of the underlying principles governing airflow around vehicles and how these principles can be harnessed to engineer more efficient designs. Electric vehicles face challenges in achieving maximum efficiency, and this article will explore the intricate science behind optimizing electric car aerodynamics. We will delve into the key design elements, discuss innovative techniques, and examine specific examples of successful applications. The structure of this article will first present an overview, followed by detailed breakdowns of core design principles, concluding with practical insights on how these principles are implemented in the real world. This exploration will ultimately equip readers with a clear understanding of the scientific basis for achieving sleek and efficient electric car aerodynamics.

Understanding the Fundamental Principles of Aerodynamics

Airflow and Vehicle Form:

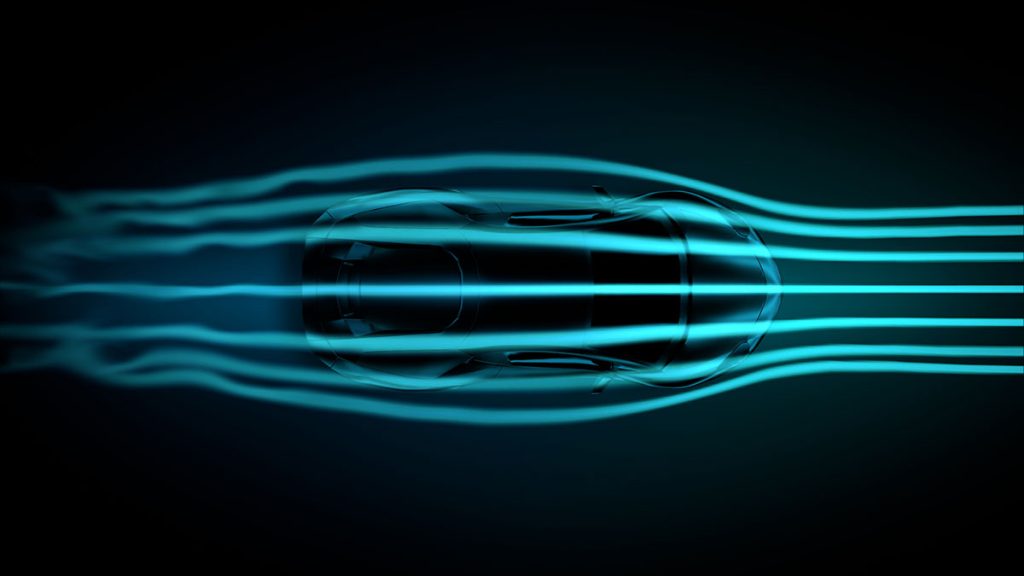

Electric car design, to maximize efficiency, must consider airflow around the vehicle. Streamlined shapes are essential to minimize drag. Aerodynamics significantly influence electric car performance and range. The shape of the vehicle’s body, including the front end, sides, and rear, drastically affects the airflow. A streamlined profile allows air to flow smoothly over the vehicle, reducing air resistance. Poorly designed vehicles experience turbulence and increased air resistance. This results in reduced range and performance, especially at higher speeds. Many factors, including the vehicle’s length and width in conjunction with its wheelbase, height, and overall design, influence the aerodynamics of the electric car.

The Role of Drag Coefficients:

The drag coefficient is a critical measure of a vehicle’s aerodynamic efficiency. A lower drag coefficient means less air resistance, translating to better fuel economy (or in this case, range). Aerodynamic efficiency is directly tied to the vehicle’s range and speed. Electric vehicles typically have complex aerodynamics, and each component of the design plays a crucial role in improving range and performance. For instance, the design of the front and rear spoilers can significantly impact the drag coefficient. Designers carefully evaluate how the vehicle interacts with the air around it. The interaction of the air and the vehicle body is analyzed to produce the optimal shape and reduce resistance to maximize efficiency.

Optimizing Air Intake and Exhaust Systems

Designing for Airflow:

Careful design of air intake and exhaust systems are essential components in creating a high-performance electric car. Air intake systems need to be strategically placed and designed to optimize airflow to the electric motors, while carefully placed exhaust systems minimize the turbulence created by the exiting gases. Efficient design directly impacts the car’s energy consumption. Proper design enables the vehicle to operate effectively at various speeds and in various environmental conditions, thereby increasing the overall range. Air intake efficiency directly impacts the performance and overall range of an electric vehicle. For example, large, strategically placed vents can improve airflow.

Minimizing Turbulence:

Turbulence negatively affects electric car performance by increasing drag. Turbulence occurs when airflow becomes chaotic and erratic, reducing the car’s efficiency. The aerodynamic design should minimize the creation of turbulence. To achieve this, designers often incorporate specialized design elements such as spoilers, underbody panels, and other aerodynamic appendages. These components are carefully positioned and tailored to the overall form of the car. Minimizing turbulence has a significant impact on the vehicle’s aerodynamic efficiency and range. Manufacturers frequently conduct detailed wind tunnel tests to assess how various designs affect airflow and turbulence.

The Importance of Wind Tunnel Testing

Unveiling Aerodynamic Insights:

Wind tunnel testing is an indispensable tool for evaluating the aerodynamic performance of electric vehicles. By placing a scaled model of the vehicle in a controlled wind environment, engineers can meticulously analyze how air flows around the vehicle. This allows them to identify areas where airflow is disrupted, leading to increased drag. This critical step in the development process allows engineers to pinpoint and address issues associated with airflow. Through repeated iterations, optimal designs emerge and increase performance.

Iterative Design and Optimization:

Wind tunnel testing enables an iterative design process for improving aerodynamics. Engineers use the results from wind tunnel tests to modify the vehicle’s design and conduct further tests. The insights gained from this feedback loop enhance the vehicle’s aerodynamic performance. Sophisticated computer simulations often accompany wind tunnel testing to validate and refine designs. These tests meticulously analyze the interaction of the car and the environment and its impact on the vehicle’s aerodynamic performance. This iterative approach ensures that electric car designs are optimized for maximum efficiency and performance.

Real-World Examples of Sleek Aerodynamics

Tesla’s Design Philosophy:

Tesla’s electric vehicles exemplify sleek and efficient designs. The brand frequently features streamlined shapes, optimized air intakes, and thoughtful exhaust systems to maximize efficiency and minimize drag. This approach demonstrates that cutting-edge design principles are critical in electric vehicle performance, and it sets a trend for other manufacturers.

Other Manufacturers’ Approaches:

Other automakers have also incorporated aerodynamic principles into their designs. Models frequently demonstrate optimized airflow and minimize turbulence, resulting in better energy efficiency. Designers have focused on creating a balance between a visually appealing and aerodynamic exterior and maximizing the range of electric vehicles. This commitment to efficiency is becoming increasingly common. The overall aim is to optimize the tradeoff between aesthetics and aerodynamics.

Advanced Design Concepts and Technologies

Active Aerodynamics:

Active aerodynamic features, such as adjustable spoilers and flaps, further enhance vehicle efficiency. These systems respond to varying driving conditions, adjusting to optimize airflow and reduce drag. This advanced feature is critical for maintaining the car’s overall efficiency in a variety of conditions. The incorporation of active aerodynamics adds another layer of complexity and refinement to the engineering of electric cars, which contributes to maximizing efficiency and minimizing drag. For instance, these active systems can be adjusted to optimize the car’s stability and handling.

Sustainable Materials:

The use of sustainable and lightweight materials also plays a crucial role in improving aerodynamics. This is increasingly important in electric vehicles, as reducing the overall weight of the vehicle enhances range and performance. The incorporation of lightweight materials further increases the energy efficiency of electric vehicles by minimizing the overall weight of the vehicle.

The Future of Electric Car Aerodynamics

The Bottom Line: Future Trends

Conclusion

FAQs

json

[

{

"question": "What are some of the key design elements that contribute to sleek and efficient electric car aerodynamics?",

"answer": "Several key design elements contribute to sleek and efficient electric car aerodynamics. These include streamlined body shapes, optimized air intakes and exhaust systems, and the careful placement of spoilers and other aerodynamic appendages. Moreover, understanding the airflow around the vehicle, including wind tunnels tests, is also essential to ensure a balance of aesthetics and efficiency."

},

{

"question": "How do electric car manufacturers leverage technology to optimize their vehicle's aerodynamics?",

"answer": "Electric car manufacturers utilize sophisticated computer simulations and advanced wind tunnel testing to optimize aerodynamics. Computer-aided design (CAD) software helps design and model the vehicle’s form factor and analyze airflow around the vehicle to identify potential inefficiencies. They also perform iterative design improvements through these processes to refine and fine-tune the performance of electric vehicles' aerodynamics."

}

]

In conclusion, sleek and efficient electric car aerodynamics are crucial for maximizing range, performance, and minimizing environmental impact. By understanding the science behind streamlining, optimizing air intake and exhaust systems, and exploring innovative design elements, manufacturers can create vehicles that are both visually appealing and environmentally responsible. For a deeper dive into the future of electric vehicle engineering, check out resources like the Society of Automotive Engineers (SAE) or similar organizations for cutting-edge research. Ultimately, this journey of technological advancement emphasizes the importance of continuous improvement in electric car design, ensuring a sustainable and thrilling future for personal transportation.