Understanding truck weight distribution is crucial for maximizing safety and efficiency in the trucking industry. A poorly distributed load can lead to decreased fuel efficiency, increased maintenance costs, and a significant safety risk. This comprehensive guide explores the intricacies of weight distribution, from the fundamentals to advanced strategies, equipping you with the knowledge needed to optimize your trucking operations. We will delve into the key factors affecting distribution, practical techniques for achieving optimal balance, and ultimately, strategies for maximizing safety and efficiency on the road. This article will cover the importance of proper weight distribution, common pitfalls to avoid, and techniques to improve performance and longevity of your trucks.

Understanding the Fundamentals of Truck Weight Distribution

The Core Concept of Equilibrium

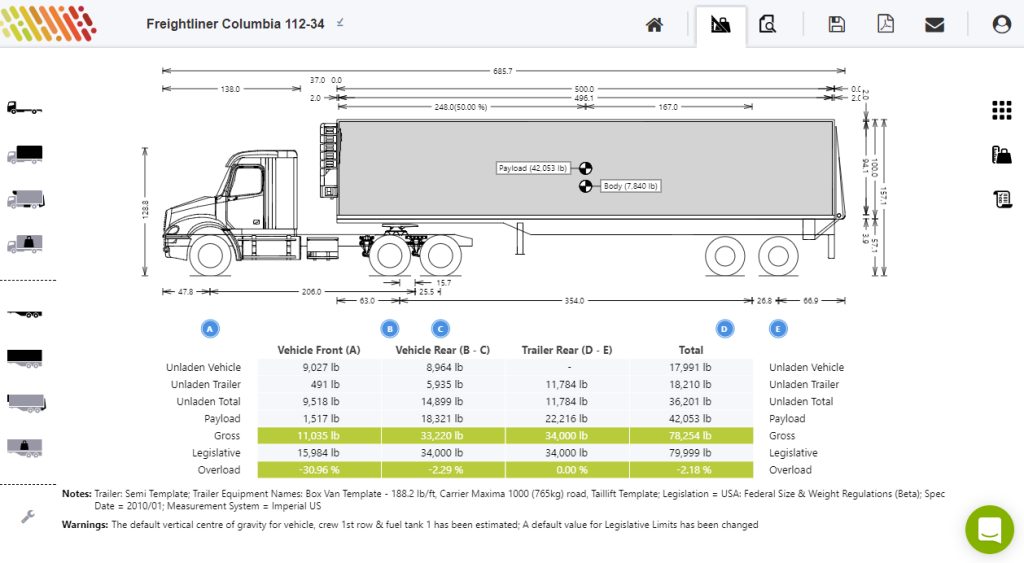

Weight distribution in trucks is fundamentally about achieving equilibrium. Every truck has specific axle weight limits, determined by the vehicle’s design and legal requirements. An even load across all axles ensures that the truck’s chassis is supported evenly, preventing excessive stress on components such as the suspension, steering, and brakes. Maintaining balance is crucial for safe handling and overall vehicle performance. Proper weight distribution is often the difference between safe operation and potentially catastrophic failure. Maintaining this equilibrium is especially important for long-haul trucking, where the risk of uneven weight distribution is amplified by the distances involved.

The Impact of Weight Distribution on Safety and Fuel Economy

Balancing Safety and Cost Effectiveness

Uneven weight distribution poses significant risks for the driver and other road users. Excessive weight on a single axle can lead to axle overloading, premature tire wear, and decreased braking efficiency. This compromise in vehicle performance can increase the likelihood of accidents, causing considerable financial and human repercussions. Beyond safety, improper weight distribution directly impacts fuel economy. A poorly balanced truck requires more energy to maintain stability and control. This translates to higher fuel consumption, which dramatically affects the profitability of the trucking operation.

Factors Influencing Truck Weight Distribution

Understanding the Variables at Play

Numerous factors affect weight distribution in trucks. The first and most significant is the cargo itself. Unevenly distributed cargo causes significant issues. The center of gravity of the load is a key consideration. If the load is unevenly distributed within the truck bed, it shifts the center of gravity, compromising the truck’s stability. Understanding the weight and density of the goods being transported is essential for proper loading. The type of vehicle and its suspension system play a critical role. Different truck designs have varying load capacity and weight distribution capacities.

Practical Techniques for Achieving Optimal Distribution

Utilizing Load Planning and Securing Methods

Careful planning is essential for achieving an even distribution of weight across the axles. Accurate weighing of the cargo is vital before loading. Load planning should account for the truck’s specific axle weight limits and any terrain or route factors that could impact the distribution. Proper cargo securing methods are also critical in ensuring that the cargo remains stationary. Heavy or bulky goods should be placed strategically within the truck to maintain the balance. Strapping, tarps, or other securing mechanisms can help stabilize loads and prevent shifting.

Advanced Strategies for Maximizing Efficiency and Safety

Leveraging Technology and Expertise

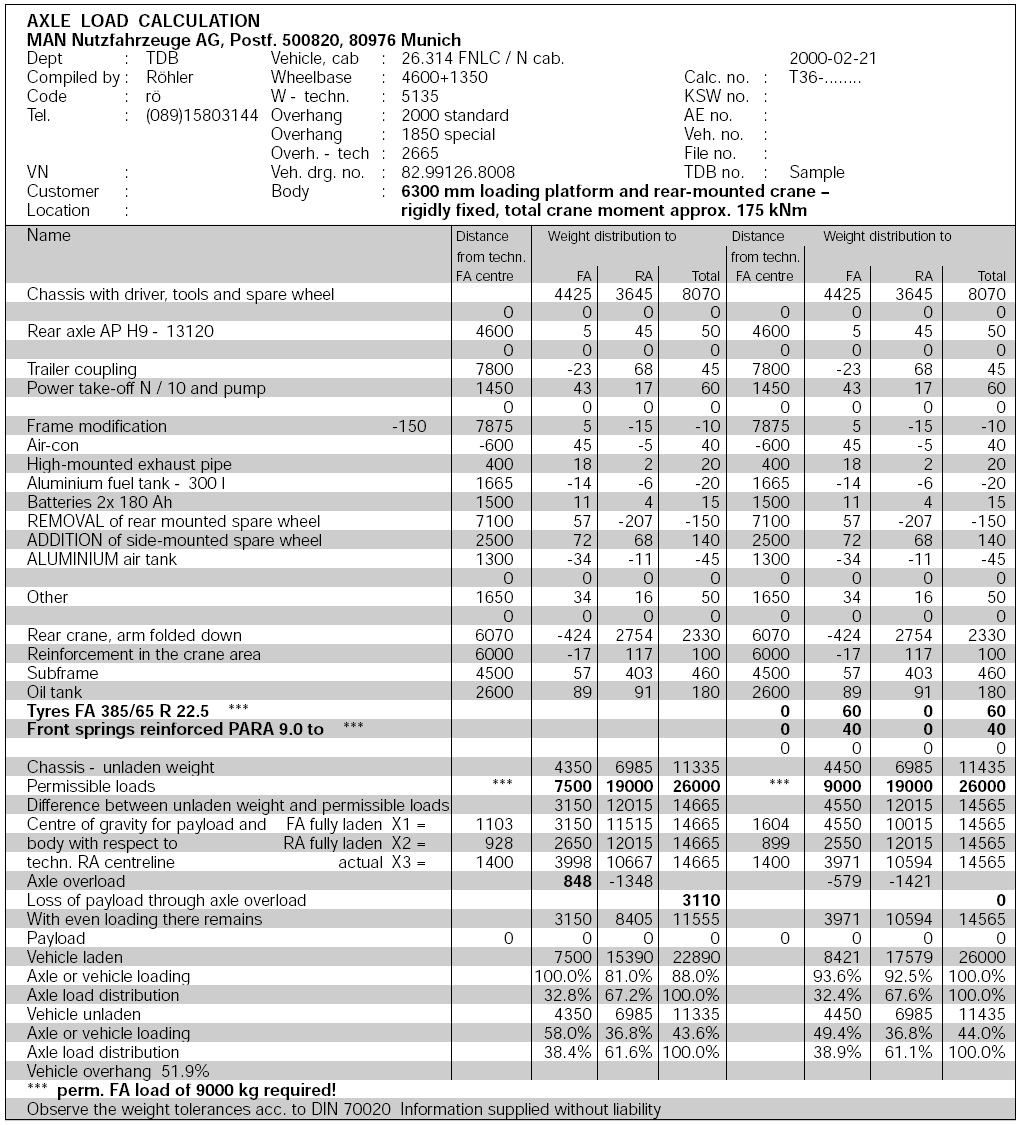

Modern technology offers advanced tools for improving weight distribution. Software programs and digital load management systems can help optimize the load distribution plan, taking into account variables like weight, center of gravity, and axle limits. Data-driven insights are also beneficial. Trucking companies can leverage these technologies to identify patterns, optimize load plans, and reduce instances of overloading or improper distribution. Consulting with experienced transportation engineers can provide critical insights into how specific loads will react on different terrains or conditions. Employing these methods will further ensure both efficiency and safety of operation.

Case Studies on Successful Weight Distribution Strategies

Real-World Examples and Best Practices

Numerous trucking companies have successfully implemented weight distribution strategies to enhance safety and profitability. One company, for example, observed significant reductions in maintenance costs and accidents after implementing a comprehensive weight distribution training program for its drivers. The implementation of digital load planning software resulted in improved fuel efficiency, leading to significant cost savings. These examples highlight the practical value of incorporating advanced technologies and methods. Best practices in weight distribution will continue to evolve as technology and expertise advances.

Implementing Weight Distribution Training Programs

Optimizing Driver Skill and Knowledge

Comprehensive training programs that address the nuances of weight distribution are critical for safety in trucking. Training programs should include practical exercises such as loading and securing goods. These programs should equip drivers with the necessary skills to recognize and correct potential weight distribution issues in real-time, ensuring a safe and reliable operation. Training emphasizes load planning and the identification of potential hazards and issues.

Regulatory Compliance and Weight Distribution Guidelines

Adherence to Laws and Regulations

Following regulations on axle weight limits is critical. State and federal regulations outline specific requirements for load weight distribution. Compliance with these regulations prevents violations, ensuring that the trucking operation remains in adherence to safety and legal standards. Violations can lead to hefty fines or even suspension of operation. Knowing and abiding by these rules will help minimize incidents and keep operations running smoothly.

FAQ

What are the common causes of weight distribution issues in trucks?

Weight distribution problems in trucks can arise from several factors, including improper loading procedures, unevenly distributed cargo, or inadequate suspension systems. A common issue is overloading a specific axle, leading to an uneven load on the vehicle’s suspension. Poorly secured cargo can shift during transit, further exacerbating weight distribution problems. Other contributing factors include using the wrong type or amount of cargo securing equipment. Understanding and addressing these issues is crucial for preventing accidents and maintaining a safe and efficient operation.

In conclusion, understanding truck weight distribution is paramount for maximizing safety and efficiency on the road. Proper distribution minimizes stress on critical components, prevents accidents, and ensures optimal fuel efficiency. By implementing the strategies discussed, trucking companies and drivers can significantly reduce risks and improve their overall operational performance. To learn more about specific weight distribution challenges in different terrains or vehicle types, consider consulting a transportation engineering professional or exploring further resources on load optimization techniques. Implementing these strategies can yield significant improvements in safety and efficiency, reducing maintenance costs and improving profitability in the long run.